VRG Controls has partnered with Oxford Flow to provide revolutionary new regulation technology to meet the needs of today’s gas pipelines and natural gas utilities. The Red Ox Regulators brand is the exclusive distributor in the USA of Oxford Flow based natural gas applications. Oxford Flow and Red Ox have “grabbed the bull by the horns” to provide innovative gas regulation solutions that ensure superior performance while exceeding the environmentally friendly demands of the industry.

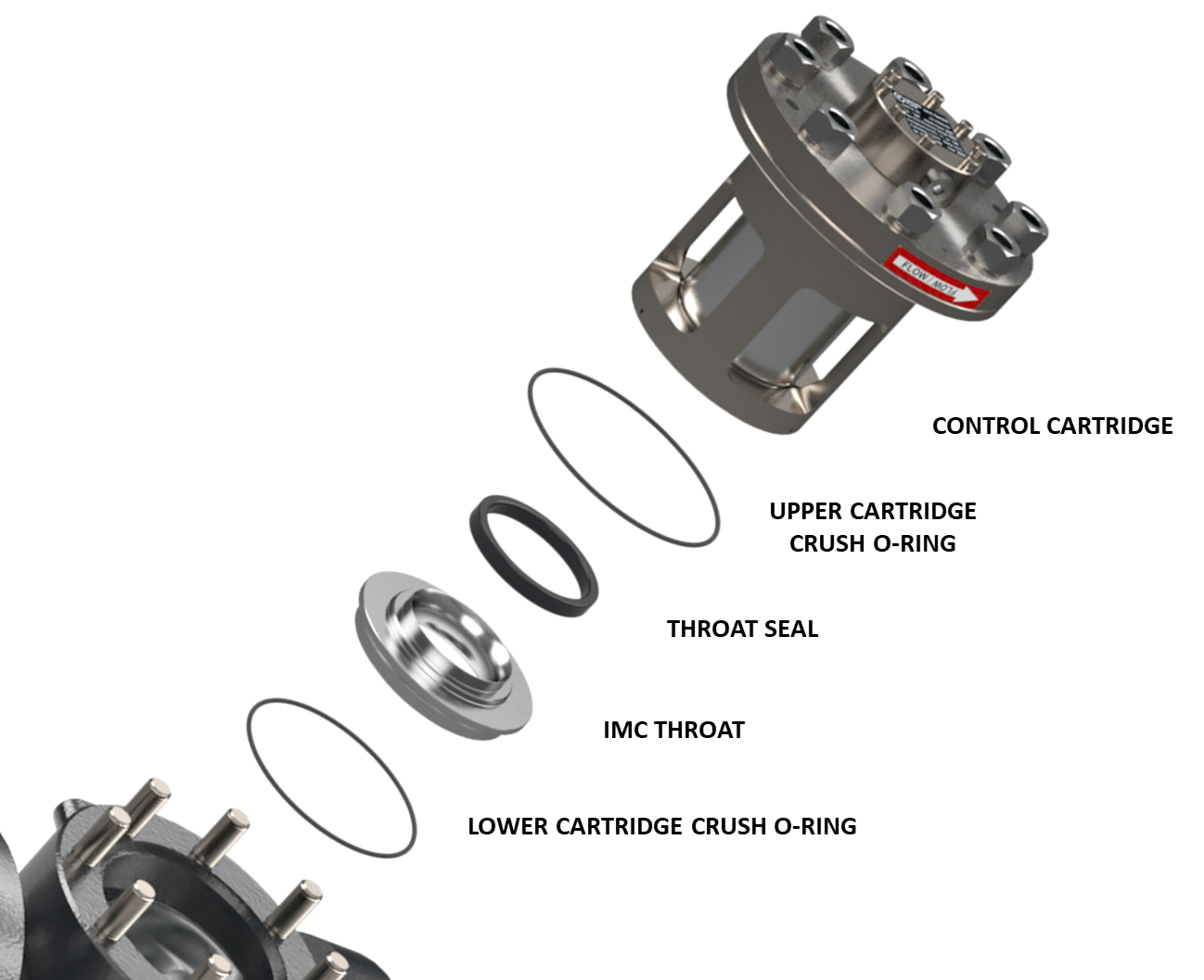

IMC (Top Entry)

Red Ox IMC series of regulators is a flanged top-entry regulator offered with ANSI 150, 300, or 600 flanges in 2”, 3”, 4”, 6”, and 8” sizes. The Red Ox IMC is a normally closed, fail open regulator featuring bubble tight lock up, full ANSI differential, and wide 2000:1 rangeability. The patented piston design and dynamic seals reduce maintenance. Manufacturer maintenance is recommended 10 years; reducing O&M costs starting immediately. Designed to be a dimensional fit to existing Top Entry style regulators.

IMS (Wafer)

Red Ox IMS series of regulators is a flangeless axial flow style regulator that can drop into ANSI 150, 300, or 600 flanges. Offered in 2”, 3”, 4”, 6”, and 8” sizes the IMS regulator is rated at 1500 PSIG but is limited by the flanges on either side of it. The dimensions of the Red Ox IMS are identical to competitor flangeless regulators rendering the IMS a drop-in solution to old, outdated axial flow technologies utilizing rubber sleeves. Much like the IMC top-entry version the Red Ox IMS is a normally closed, fail open regulator featuring bubble tight lock up, full ANSI differential, and wide 2000:1 rangeability. With the patented piston design and two dymanic seals maintenance intervals are extended to a manufacturer recommended 10 years; reducing O&M costs starting immediately.

2” IMS - IMC Size Comparison

Regulator Pilots

VRG Controls engineers and manufactures high performance pneumatic pressure pilots suited for the regulator market. The Regulator Pilots (RP) share technology, and components, with the industry leading VPC series of pilot controllers. While the VPC offers PID control, the RP is a proportional pilot specifically designed to control loading and unloading style regulators. These Regulator Pilots (RP’s) represent the next generation of proportional pilots with two unique offerings, the OS (Open-Spring) and the CS (Closed-Spring) series.

Red Ox Accessories

From brackets, to filters, to noise attenuation, these popular accessories are designed to enhance performance and increase longevity.

Red Ox Pilot Mount

The IMC RP Pilot Mounting Bracket provides a robust, convenient ability to mount VRG Controls’ RP Series Regulator Pilots. The 316SS bracket can be installed on LEFT or RIGHT hand side of all sizes of Red Ox IMC Top Entry Regulators. The bracket allows the IMC Top Entry Regulator to be rebuilt without removal of the RP Pilot.

Eliminator Filter

The Eliminator Pilot Filter provides 20µ filtration of pilot inlet gas to ensure reliable operation of your Red Ox control devices. The Eliminator features 316 Stainless Steel construction in a compact design with 0.250 FNPT inlet, outlet and drain connections. The standard sintered polyethylene filter element can easily be changed inline.

Inlet / Outlet: 0.250 FNPT

MAOP: 5000 psig

Filtration: 50µ

Body: 316L Stainless Steel

Media: Sintered Polyethylene

Filter Dryer Assembly

The FD Series of Filter assemblies provide high capacity, long-life 10 µ filtration. The FD Series features a heavy-duty, high-pressure carbon steel construction with 0.250 FNPT inlet, outlet and drain connections. Various filter/dryer media filters are available to remove entrained moisture, gas odorant and trace sulfur.

Inlet / Outlet: 0.250 FNPT

Drain: 0.250 FNPT w Needle Valve

MAOP: 1500 psig

Filtration: 3µ

Body: Painted Carbon Steel

Media: Silica Gel - Standard

Sulfa-Gon - Optional

Activated Charcoal - Optional

Drilled Hole Diffuser

IMC Red Ox Regulators can be supplied or retrofitted with the IMC Series Drilled Hole Diffuser. The Drilled Hole Diffuser provides noise attenuation typically in excess of 10 dBA when applied to IMC Red Ox Regulators without any significant loss of flow capacity. The Drilled Hole Diffuser is ideal for applications that have the potential to exhibit potential for aerodynamic noise.

Available Versions:

Fine and Coarse

Compatible Models:

IMC Series

Compatible Sizes:

2, 3, 4, 6, 8 in Bore

Application:

Prevention of Excess Aerodynamic Noise

Noise Attenuating Jacket

NAJ Series Noise Attenuating Jackets provide excellent acoustic noise reduction when paired with Red Ox Regulators. Noise attenuation can typically be reduced between 12-25 dBA when applied to aggressive regulation applications. The NAJ offers a cost-effective solution during design stage or retrofit to existing “problem” facilities. NAJ Jackets are equipped with easy removal and reinstallation without special tools or material.

Travel Limiter

IMC and IMS Red Ox Regulators can be supplied or retrofit with the IM SERIES TRAVEL LIMITER. The Travel Limiter restricts the opening travel of IMC or IMS Red Ox Regulators. The Travel Limit restricts the full open flow without compromising controllability. Flow restriction can be beneficial when considering overpressure and relief valve sizing requirements.

Available Travel Limits: 25%, 50%, 75% Limit

Compatible Models: IMC and IMS Series

Compatible Sizes: 2, 3, 4, 6, 8 in Bore

Applications:

•Max Flow Restriction

•Improve Efficiency of Relief Valve Sizing and Selection

•Prevention of Excess Noise or Flow Velocity

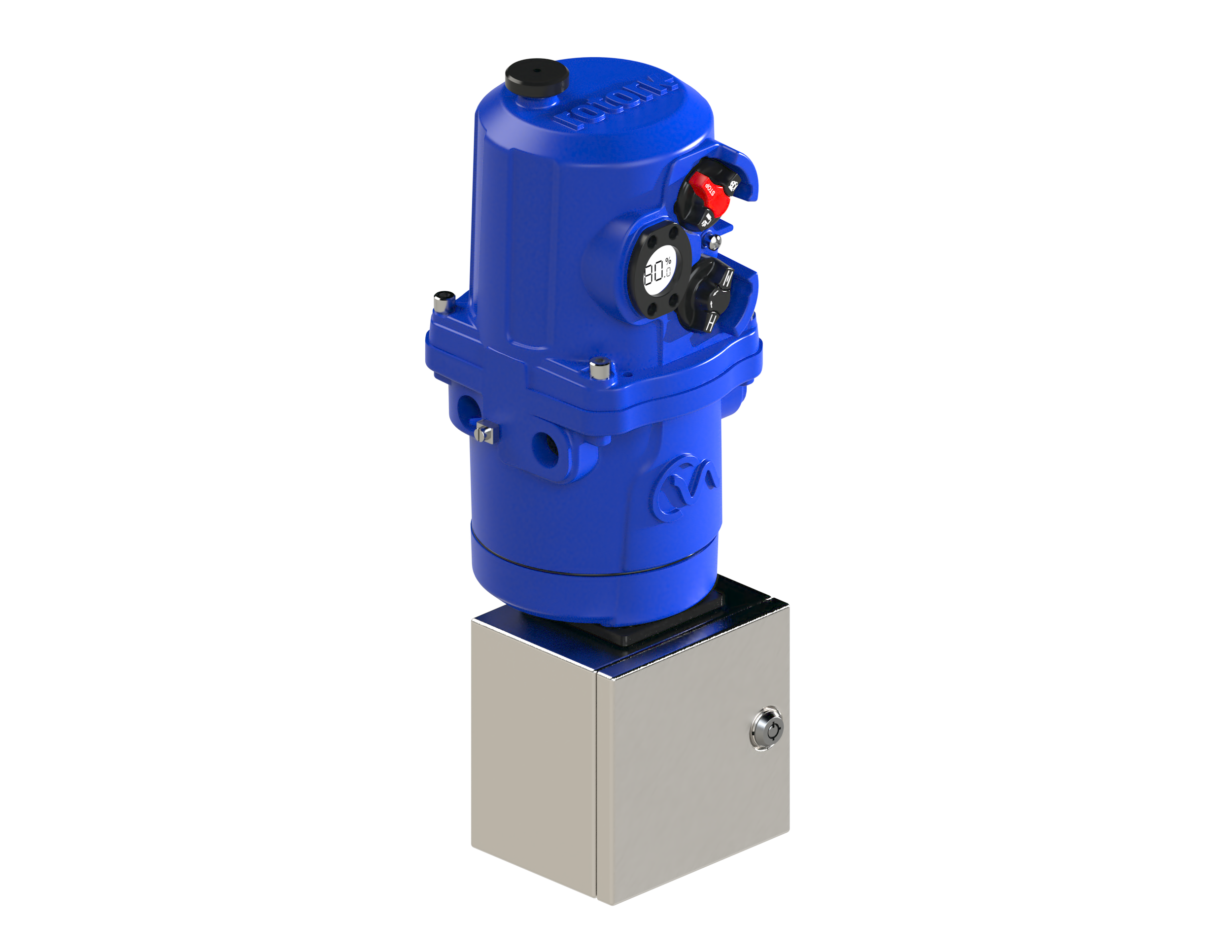

Electronic Setpoint Controller

Electronic setpoint control module provides remote setpoint adjustment capability when paired with VRG Controls’ RP Series Regulator Pilots. ESC modules may be powered with 120 or 24 VDC Power. 4-20 mA analog or 24 VDC discrete command signal will raise / lower pressure setpoint. In event of loss of command signal or power, the ESC will render the RP pilot to “lock” at last pressure setpoint, thereby maintaining control of the process. The ESC features an easy pushbutton programming and 4-20 mA feedback of ESC motor position.

Research Control Valve

The Model RCV research Control Valve is a pneumatically operated control valve that is used in conjunction with Red Ox Regulators to provide control of a variety of processes. The RCV is typically used for flow control, remote electronic control, or “droopless” pressure control. The RCV is available in “fail open” or “fail closed” configurations.

Input: 3-15 psig, 6-30 psig, Split Range Capable

Failure Modes: Fail Open or Fail Closed

Applications:

•Cascade Control / Velocity Control

•Flow Control

•Droopless Pressure Control

•Electronic Pressure Control

•Override Applications

The Vortex Pilot Gas Heater (VPGH) protects the Red Ox pilots from freezing off. The Vortex Pilot Gas heater is Class 1, Division 1 explosion proof device that meets and/or exceeds all federal and state requirements for regulator station design and applications. Having a maximum heat gain of 90 degrees Fahrenheit, there is no chance of Red Ox pilots being overheated.

Pilot Gas Heater

ES Stemless Axial Flow Valve

The ES stemless valves offer world class performance, reliability and emissions control for a wide range of severe service applications in oil and gas, petrochemical and process industries. The ES stemless valves can also be used for transitioning energy systems, including hydrogen and biomethane applications. The ES provides zero-leakage isolation in a variety of materials and configurations from 2″ to 24″ (DN50 to DN600) and in pressures classes to ASME 2500#.

Transformed valve performance

The zero emission ES stemless axial flow valves have fundamentally transformed valve performance. Because the ES stemless valves do not have an external stem, there is no possibility of fugitive emissions through stem packing leaks. Further, because it does not have a mechanical drive train, it is not subject to stresses and side loading that cause poor performance and premature mechanical failure in other valve types.

Significantly reduced size and weight

With its pressure-balanced trim, the ES can be operated by a compact Electrohydraulic Powerpack, significantly reducing the size and weight of the valve package.

Reduced erosion and long-term zero leakage

The valve internals are also designed to provide very high flow rates while minimising turbulence. This reduces erosion on sealing surfaces and allows the ES to provide long-term zero leakage in a variety of severe applications.

Designed to operate at restricted flow and high differential pressure

ES withstands high velocities with no cavitation while maintaining tight shutoff.

ES will reduce process downtime caused by valve failure.

Does not have an external stem (a primary source of emissions)

ES does not require stem packing and maintenance to meet emissions requirements.

ES eliminates stem emissions, reducing OPEX related to valve packing.

Utilizes an Electrohydraulic Powerpack (rather than a conventional actuator)

The Electrohydraulic Powerpack is compact, efficient in transmitting force, and only requires 24VDC power and a control signal.

The Electrohydraulic Powerpack reduces valve package size and weight by 50% and reduces installation cost by 30%.