VRG Controls engineers and manufactures high performance control valves and control instrumentation for natural gas regulation. VRG control instrumentation features simplicity and reliability specifically designed for gas pipeline applications. Our philosophy is to provide the highest quality instrumentation in tandem with an environmentally responsible approach. All VRG control instrumentation features zero emissions capabilities that are good for the environment. Our personnel leads the industry in operational experience and design expertise related to control solutions at natural gas measurement & regulation facilities. We provide unparalleled product support with industry experience unmatched by our competition.

Looking for our line of pressure regulators?

Looking for our electro-hydraulic valve controllers?

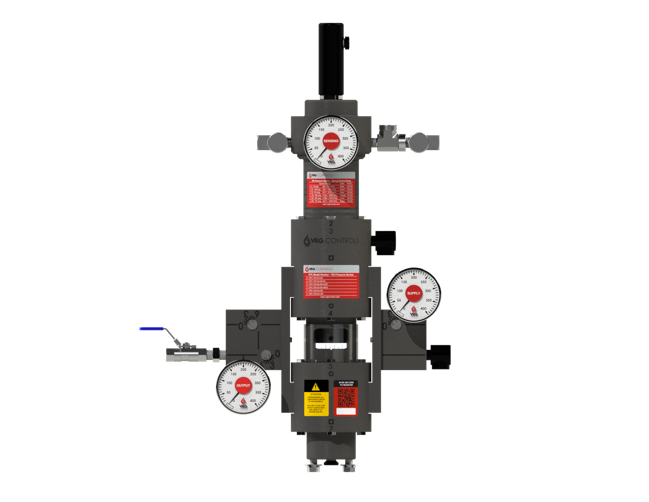

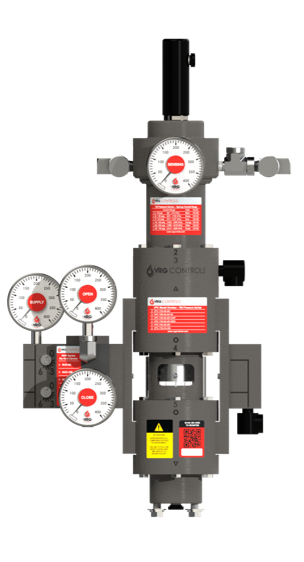

Valve Pilot Controllers

VRG Valve Pilot Controllers (VPC’s) represent the next generation of pilot-type controllers for gas pressure control applications. With many accessories, add-ons, and manifolds available just a single valve platform has many different configuration options, including ZERO emissions options.

Double Acting Pilots

Single Acting Pilots

GAP Pilot

RCVC Red Circle Valve Controller

The VRG Red Circle Valve Controller provides accurate positioning of natural gas control valves via electronic signal. The RCVC can accept analog or discrete input signals. The RCVC is compatible with all VRG Controls control valve actuators and may also be installed on virtually any design of pneumatic control valve actuator. The Red Circle Control Valve features zero steady state consumption with an ability to discharge emissions to a suitable nearby pressure system. The high pressure capability of the RCVC system allows for efficient use of more compact pneumatic actuators. The RCVC is equipped with the most advanced programmable control capabilities, diagnostics and operational features to ensure the highest performance and easiest integration on new or retrofit applications.

VMO Valve Manual Override

VMO Valve Manual Override is the ideal device to provide manual operation of pneumatically actuated control valves. The VMO allows the operator to override primary control instrumentation and position the actuated valve in open, closed or any intermediate position.

VGP-100 Valve Gas Positioner

The VGP is a pneumatic valve positioner designed to position a pneumatically actuated control valve proportional to a pneumatic command signal. Providing a modular plug and play pneumatic valve positioner system the VGP can be used with a wide array of pneumatically actuated control valves. With it’s modular design you can use the VGP’s single platform combined with the three available manifolds to control single acting and double acting valves.

Linear Control Valves

VRG Controls’ Linear Control Valves are ideally suited for natural gas control applications. They can accommodate moderate and severe service. The cage guided design features trim options to address characterized flow and noise attenuation per application. The modular format can accept a variety of actuator and trim configurations and actuators to match your application needs.

The linear control valves are ideal for:

Low to Moderate Flow Rates

Aggressive Pressure Drop Applications

Power Plant Fuel Gas Feed

“Trim” Type Control Runs

Natural Gas Transmission Pipelines

Natural Gas LDC Gate Stations

PRCV Pipeline Rotary Control Valves

PRCV Pipeline Rotary Control Valves are rugged, trunnion mounted configuration with the durable features necessary for reliability and high performance in natural gas control applications. The high capacity design of the PRCV-FP series provides a full opening, high capacity design with high flow range-ability. Higher performance trims are available in our PRCV-STH1, PRCV-STH2 and PRCV-STHP series to provides additional noise attenuation and extended flow range-ability. The trunnion platform is equipped with VRG Control Specification features necessary to ensure maximum control accuracy and reliability for gas pipeline regulation applications. The PRCV mates seamlessly with VRG RHPA double acting and spring return actuators and control instrumentation to create the highest performance pipeline control valve package on market. The PRCV-FP Series can incorporate the Below Ground configuration when utilizing RHPA Series Actuators for maximum noise attenuation with maximum capacity and lowest cost.

Size Range: 2 in to 42 in*

Design Standard: API-6D / ASME B16.5 / API 6FA

ANSI Range: 150 – 1500 ANSI

End Connections: RFFE, Weld, RTJ, Combo

Available Models: PRCV-FP, PRCV-STH1, PRCV-STH2, PRCV-STHP, PRCV-STH4, PRCV-STH5

ES Stemless Axial Flow Valve

The ES stemless valves offer world class performance, reliability and emissions control for a wide range of severe service applications in oil and gas, petrochemical and process industries. The ES stemless valves can also be used for transitioning energy systems, including hydrogen and biomethane applications. The ES provides zero-leakage isolation in a variety of materials and configurations from 2″ to 24″ (DN50 to DN600) and in pressures classes to ASME 2500#.

Transformed valve performance

The zero emission ES stemless axial flow valves have fundamentally transformed valve performance. Because the ES stemless valves do not have an external stem, there is no possibility of fugitive emissions through stem packing leaks. Further, because it does not have a mechanical drive train, it is not subject to stresses and side loading that cause poor performance and premature mechanical failure in other valve types.

Significantly reduced size and weight

With its pressure-balanced trim, the ES can be operated by a compact Electrohydraulic Powerpack, significantly reducing the size and weight of the valve package.

Reduced erosion and long-term zero leakage

The valve internals are also designed to provide very high flow rates while minimising turbulence. This reduces erosion on sealing surfaces and allows the ES to provide long-term zero leakage in a variety of severe applications.

Designed to operate at restricted flow and high differential pressure

ES withstands high velocities with no cavitation while maintaining tight shutoff.

ES will reduce process downtime caused by valve failure.

Does not have an external stem (a primary source of emissions)

ES does not require stem packing and maintenance to meet emissions requirements.

ES eliminates stem emissions, reducing OPEX related to valve packing.

Utilizes an Electrohydraulic Powerpack (rather than a conventional actuator)

The Electrohydraulic Powerpack is compact, efficient in transmitting force, and only requires 24VDC power and a control signal.

The Electrohydraulic Powerpack reduces valve package size and weight by 50% and reduces installation cost by 30%.